|

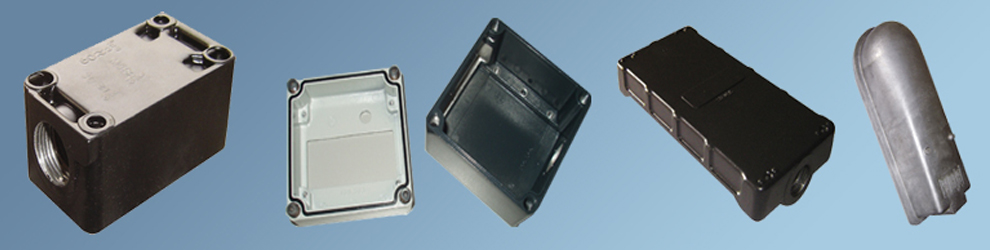

ARKO ENGINEERS DIE CASTERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

|

ARKO ENGINEERS DIE CASTERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

For an immediate response, please call this

number 08045475171

Price: